- Vacuum Annealing Furnace 1800¡ãC

- Vacuum Sintering Furnace

- Heat Treatment Furnace

- Drop Bottom Sintering Furnace

- Car Bottom Furnace

- Roller Hearth Furnace

- Mesh Belt Furnace

- Continuous Mesh Belt Furnace

- Ceramic Tiles Roller Furnace

- Roller Kiln

- Industrial Kilns

- Shuttle Kiln

- Tunnel Kilns

- Bogie Hearth Furnaces

- Rotary Kilns

- Pusher Kilns

- Ceramic Roller Kilns

- Sintering Furnace

- Annealing Furnace

- Vacuum Heat Treatment Furnace

- Vacuum Hardening Furnace

- Tempering Furnace

- Continuous Heating Furnace

- Crucible Furnace

- Glass Melting Furnace

- Muffle Furnace

- Gold Melting Furnace

West Of Kelong South Road, Luoxin Industrial Park, Xinan County, Luoyang, Henan, China.

+86-379-60193738

Rotary Kilns

- Brand Name: Luwei

- Model: Rotary kiln / Furnace

- Max.Temperature: 1000°C

- Working Temperature: 800°C

- Furnace Chamber Size: 13000x800mm

- Temperature Controller: PID automatic control via SCR

- Control Accuray: ± 1°C

- Heating Element: SiC heaters

- Thermocouple: S type

- Chamber Material: High quality heat resistant alumina ceramic plates with 50mm thick and mullite bricks

A Rotary Kilns is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing.

Rotary kilns work by processing material in a rotating drum at high temperatures for a specified retention time to cause a physical change or chemical reaction in the material being processed. Rotary Kilns — rotating industrial drying ovens — are used for a wide variety of applications including processing raw minerals and feedstocks as well as heat-treating hazardous wastes.

Rotary Kiln / Furnace is mainly used for metallurgical industry, iron and steel plant iron ore roasting, chromium, nickel ore roasting, refractory plant roasting high bauxite ore and aluminum roasting clinker, aluminum hydroxide, chemical plant roasting chrome ore and chrome powder minerals.

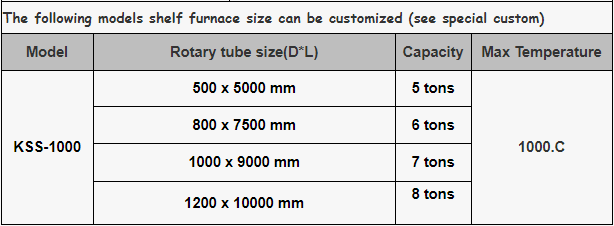

Technical Specifications of Rotary kilns |

|

Rotary kiln usage |

In the production of building materials, metallurgy, chemical industry, environmental protection and many other production industries,rotary kiln equipment is widely used for mechanical, physical or chemical treatment of solid materials. |

Kiln type |

Rotary kiln type |

Max. temperature |

1000°C |

Working temperature |

RT=800°C ( >5 hrs) |

Rotary tube size |

1200x13000mm(D*L) |

Temperature controlling |

30 segments programable and PID auto control |

Heating elements: |

High performance SIC heater with three sides or four sids |

Thermocouple: |

Long Life K Type Thermocouple |

Heating rate |

0~20°C / min (suggestion =< 10°C) |

Temperature accuracy |

±1°C |

Wok voltage: |

AC380V, 50Hz(or as your requirement) |

Furnace temperature field uniformity |

±1℃( according to the heating chamber size and can multi point temperature control) |

Temperature controller : |

SCR control, PID parameter self-setting function rapid temp compensation. |

30 programmable segments for precise control |

|

Built in protection for over-heated and broken thermal couple. |

|

Large digital control panel for easy operation |

|

Furnace chamber materials: |

High quality heat resistant alumina ceramic plates with 50mm thick and mullite bricks |

Heating power |

360 KW |

Temperature zone control |

6 indenpendently controlled heating zone |

Rotary tube rotational speed |

0-5 rad/min,continuous stepless adjustable |

Rotary kiln tilt angle |

0°C - 3°C |

Production capacity |

8 tons/day |

Optional items: |

PC data recorder, Exhauster port, Over temperature controller |