- Vacuum Annealing Furnace 1800▲C

- Vacuum Sintering Furnace

- Heat Treatment Furnace

- Drop Bottom Sintering Furnace

- Car Bottom Furnace

- Roller Hearth Furnace

- Mesh Belt Furnace

- Continuous Mesh Belt Furnace

- Ceramic Tiles Roller Furnace

- Roller Kiln

- Industrial Kilns

- Shuttle Kiln

- Tunnel Kilns

- Bogie Hearth Furnaces

- Rotary Kilns

- Pusher Kilns

- Ceramic Roller Kilns

- Sintering Furnace

- Annealing Furnace

- Vacuum Heat Treatment Furnace

- Vacuum Hardening Furnace

- Tempering Furnace

- Continuous Heating Furnace

- Crucible Furnace

- Glass Melting Furnace

- Muffle Furnace

- Gold Melting Furnace

West Of Kelong South Road, Luoxin Industrial Park, Xinan County, Luoyang, Henan, China.

+86-379-60193738

Muffle Furnace

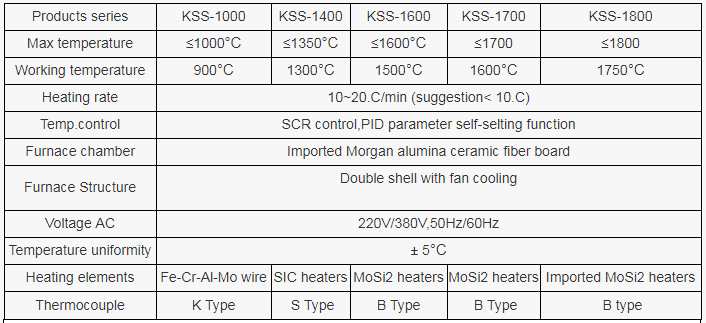

- Brand Name: Luwei

- Model: Muffle Furnace KSS-1700째C

- Max.Temperature: 1700째C

- Working Temperature: 1600째C

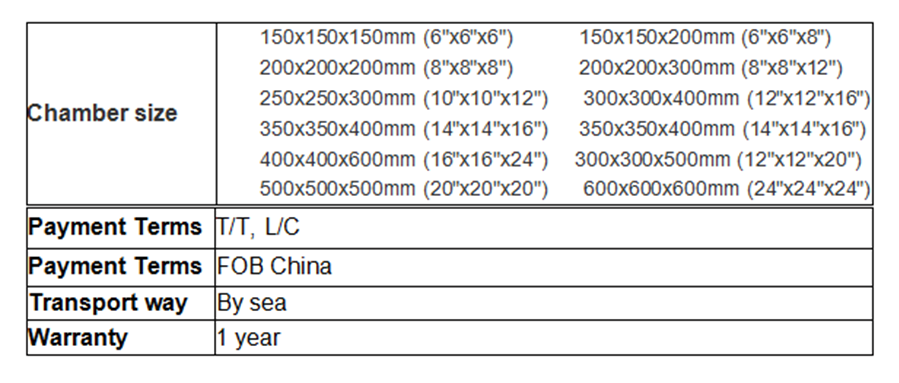

- Furnace Chamber Size: 200*200*200MM

- Temperature Controller: PID automatic control via SCR

- Control Accuray: 짹 1째C

- Heating Element: MoSi2 heaters

- Thermocouple: B type

- Chamber Material: High quality heat resistant alumina ceramic plates with 50mm thick and mullite bricks

A muffle furnace (sometimes retort furnace in historical usage) is a furnace in which the subject material is isolated from the fuel and all of the products of combustion, including gases and flying ash.[1] After the development of high-temperature electric heating elements and widespread electrification in developed countries, new muffle furnaces quickly moved to electric designs.

Today, a muffle furnace is usually a front-loading box or tube design used for high-temperature applications such as melting glass, creating enamel coatings, technical ceramics or soldering and brazing. They are also used in many research facilities to determine what proportion of a sample is non-combustible and non-volatile (i.e. ash).

Different inner chamber materials with different temperature. Temperature range from 1000째C - 1800째C. Muffle Furnace is High purity alumina fiber insulation and Morgan materials brick PID automatic control via SCR (Silicon Controlled Rectifier) power control with phase angle fired current limiting resistor. 16 programmable segments for precise control of heating rate.

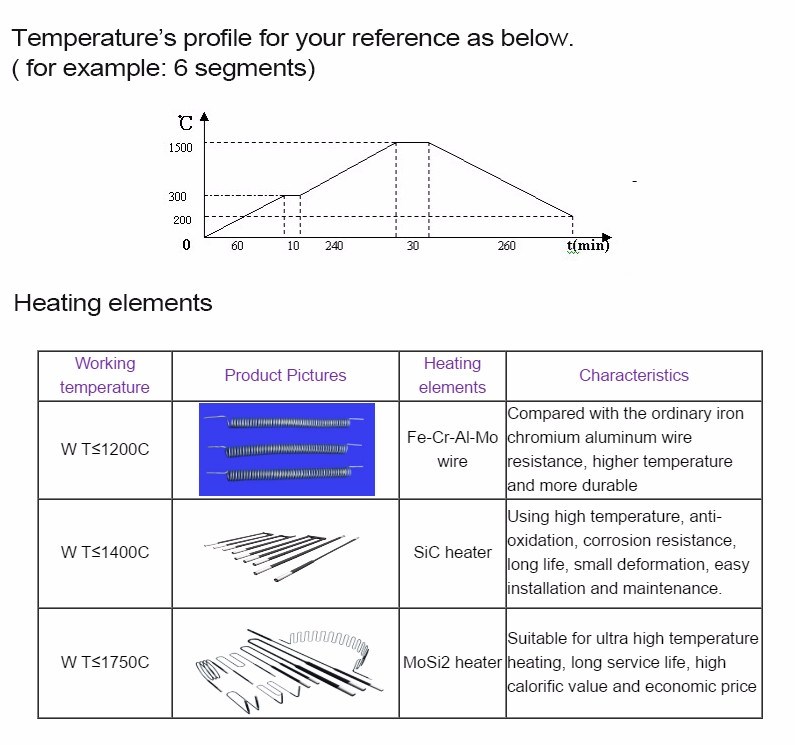

Gold Melting Furnace heat up and cool down temperature VS time graph without loading: