- Vacuum Annealing Furnace 1800¡ãC

- Vacuum Sintering Furnace

- Heat Treatment Furnace

- Drop Bottom Sintering Furnace

- Car Bottom Furnace

- Roller Hearth Furnace

- Mesh Belt Furnace

- Continuous Mesh Belt Furnace

- Ceramic Tiles Roller Furnace

- Roller Kiln

- Industrial Kilns

- Shuttle Kiln

- Tunnel Kilns

- Bogie Hearth Furnaces

- Rotary Kilns

- Pusher Kilns

- Ceramic Roller Kilns

- Sintering Furnace

- Annealing Furnace

- Vacuum Heat Treatment Furnace

- Vacuum Hardening Furnace

- Tempering Furnace

- Continuous Heating Furnace

- Crucible Furnace

- Glass Melting Furnace

- Muffle Furnace

- Gold Melting Furnace

West Of Kelong South Road, Luoxin Industrial Park, Xinan County, Luoyang, Henan, China.

+86-379-60193738

Car Bottom Furnace

- Brand Name: Luwei

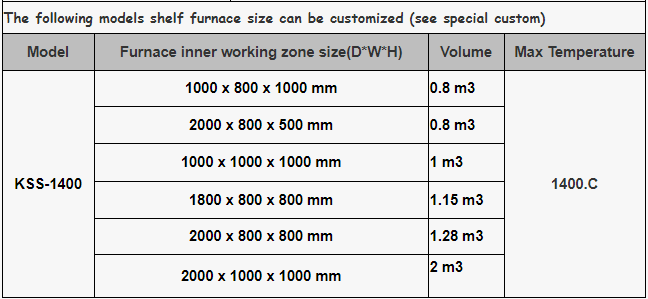

- Model: KSS-1400

- Max.Temperature: 1400°C

- Working Temperature: 1300°C

- Furnace Chamber Size: 1800*1200*1200MM

- Temperature Controller: PID automatic control via SCR

- Control Accuray: ± 1°C

- Heating Element: SiC heaters

- Thermocouple: S type

- Chamber Material: High quality heat resistant alumina ceramic plates with 50mm thick and mullite bricks

Car Bottom Furnace is also called as Shuttle Furnace Car Bottom Furnace and Pottery Kiln. Car Bottom Furnace is welded for heating treatment ceramic tiles/bricks, sintering glass materials, pottery, sintering kinds of ceramics, heating treatment for metals and heat treatment of the new materials and composite materials.

The design of a Car Bottom Furnace incorporates a rail mounted product car to transfer parts into and out of the furnace. The Car Bottom Furnace is an excellent solution to heat-treat large and heavy welded fabrications such as gear blanks, oil drill pipe, drive shafts, and similar type products.

1200°C degree 1600°C degree metal or ceramics heat treatment furnace Car Bottom Furnace is welded by steel and profiled steel; furnace chamber is ceramic fiber and high quality electric resistance wire/SiC heaters, which can save 40% energy than brick furnace chamber. Car Bottom Furnace is mainly used for annealing, normalizing and stress relieving of bars and tubes, forgings, large weldments and castings.

Technical Specifications of Car Bottom Furnace |

|

Furnace construction |

Energy,furnace chamber used Morgan materials imported fibers, high purity ceramicfiber insulation( energy saving 40% and weight lighter about 50% than old furnace). |

Big yield capacity and high productivity, especially used for heating treatment of small or medium products. |

|

Double layers carbon steel casing with fan cooling to ensure the surface of furnace below 50°C |

|

Chamber size |

1800(L)*1200(W)*1200(H) |

Max. temperature |

1400°C (<2hour) |

Working temperature |

RT=1300°C ( >5 hrs) |

Kiln open mode: |

Front loading trolley kiln with manual operation |

Temperature controlling |

30 segments programable and PID auto control |

Heating elements: |

High performance SIC heater with three sides or four sids |

Thermocouple: |

Long Life S Type Thermocouple |

Heating rate |

0~20°C / min (suggestion =< 10°C) |

Temperature accuracy |

±1°C |

Wok voltage: |

AC220V/380V, 50/60Hz(or as your requirement) |

Furnace temperature field uniformity |

±1℃( according to the heating chamber size and can multi point temperature control) |

Temperature controller : |

SCR control, PID parameter self-setting function rapid temp compensation. |

30 programmable segments for precise control |

|

Built in protection for over-heated and broken thermal couple. |

|

Large digital control panel for easy operation |

|

Furnace chamber materials: |

High quality heat resistant alumina ceramic plates with 50mm thick and mullite bricks |

Heating power |

80 KW |

Net weight(Kgs): |

2500kg |

Warranty: |

1 year limited warranty |

Certificate: |

CE certified |

Optional items: |

PC data recorder, Exhauster port, Over temperature controller |